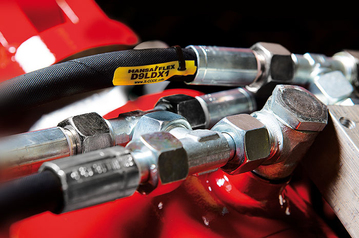

Hydraulics expertise from a single source

With HANSA-FLEX Solutions you benefit from fast help with spare parts and service modules, designed to optimise OEM production processes.

Tight deadlines, fierce competition and increasing cost pressures force companies to continuously optimise the purchase of spare parts, manufacturing and work processes as well as minimising costs.

Fast spare parts logistics

Getting hold of spare parts is no problem thanks to HANSA-FLEX. A dense network of branches ensures ready access to the components you require, even at short notice.

We can offer such efficiency as we hold over 82,000 different parts permanently in stock. Then there is our experienced and committed workforce. With their expertise and focus on service they provide fast, qualified help in any situation.

High-performance OEM concepts

No matter whether you as an OEM want to streamline logistics, improve mobility or boost productivity: HANSA-FLEX Solutions will cater for your objectives in the smallest detail.

Service modules such as "kanban and consignment warehouses", "kitting" and "works in works" prove to be especially cost-effective. These OEM services are customised and carefully coordinated with your production process cycles. X-CODE, hydraulic workshops and the HANSA-FLEX Fluid Service offer other options for cutting costs.

Kanban and consignment warehouses

An increasing number of OEMs are relying on the system partnership of HANSA-FLEX Solutions to optimise their production processes and logistics. They are looking for joint concepts that allow added value to be systematically increased for customers. HANSA-FLEX develops such concepts. Logistics solutions we have already created in close cooperation with OEMs include kanban and consignment warehouses.

HANSA-FLEX kanban warehouses offer you an on-site, structured and regularly maintained stock of hydraulic parts for your production lines. The products required are always to hand for fitters. Doing away with any need for time-consuming planning and ordering.

Kanban warehouses can also be run as consignment warehouses. This means that the parts initially remain in HANSA-FLEX's possession and only become a cost factor with stock withdrawals. With this principle you only pay for what you actually need.

Kitting

Fluid technology is a complex affair. Fitters do not just have to install hose lines, but also many associated components such as fastening elements, insulating materials or electronic parts. It is a time-consuming and cost-intensive process, ordering the required parts from the different manufacturers and organising their supply to the fitting team. This is where the HANSA-FLEX kitting module comes in.

Kitting means the supply of assembly kits ready for installation that not only include the HANSA-FLEX components, but also all the parts from third-party suppliers required for each installation stage. We get together with your company to develop complete kits, including the organisation of the parts for removal and optimum packaging. This principle offers maximum reliability: wrong or missing parts become a thing of the past. Interfaces are reduced and initial costs minimised, while productivity is given a permanent boost.

Works-in-works

The "works-in-works" concept provides for full integration of HANSA-FLEX services and products in your manufacturing processes – including shift operation. HANSA-FLEX maintains a production workshop with a specified stock of spare parts and all equipment at your company. The benefits are obvious: You do not need your own stock of parts for fluid technology. So doing away with the costs of warehousing, financing the stored goods or the costs of internal logistics.

You can forget about wrong orders and charging off goods that are superfluous or surplus to needs. The response times for product delivery, manufacturing spare parts or building prototypes are extremely short. Making your operations very flexible. There is always someone about to discuss all technical or commercial issues on site. The HANSA-FLEX SOLUTIONS fast and direct communication system ensures everything goes without a hitch. This will also allow you to cater for a short-term increased production requirement without difficulty at any time.